Precision Adjust Elite – A Closer Look At Edge Results

What distinguishes the edge produced by the Original Precision Adjust from the edge achievable with the Precision Adjust Elite? To explore this, we'll closely examine the results using a digital microscope.

To conduct the comparison, we utilized two Kershaw Leek knives, both brand new, and subjected them to sharpening on each system. Given their relatively soft steel, these knives are easy to sharpen. Employing the "push" technique, where the stone is pushed into the knife while moving along the edge slightly, we aimed to create an even scratch pattern that replicates a factory edge. We ensured a consistent timeframe for each grit in the progression to maintain uniformity across stages.

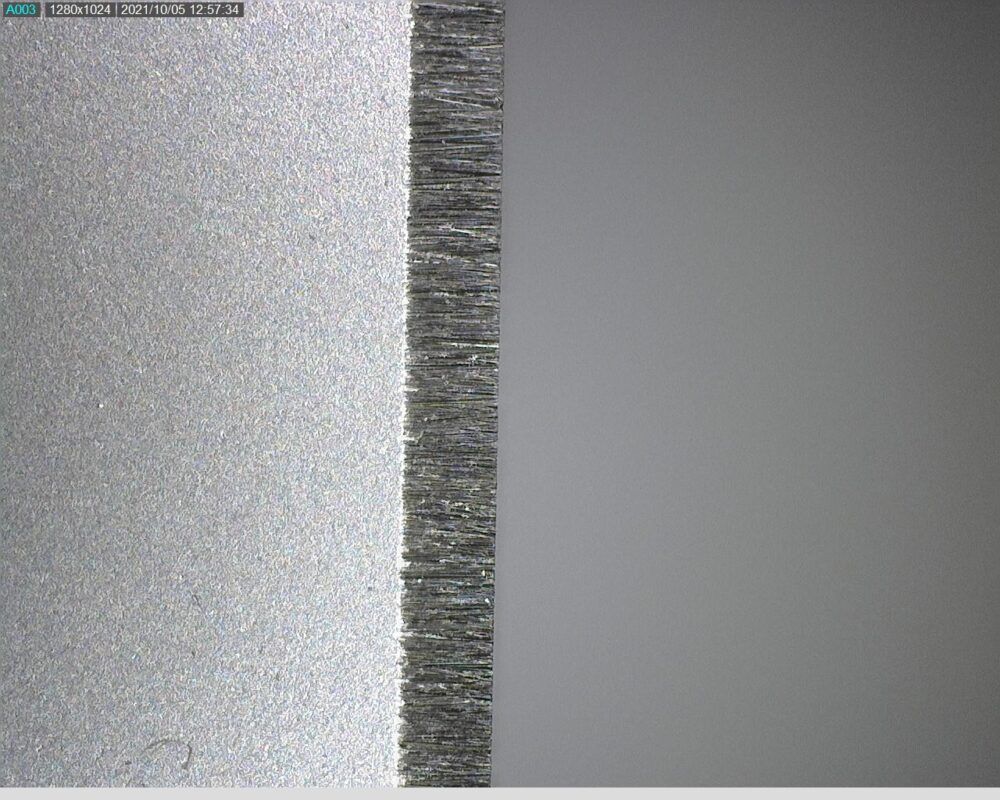

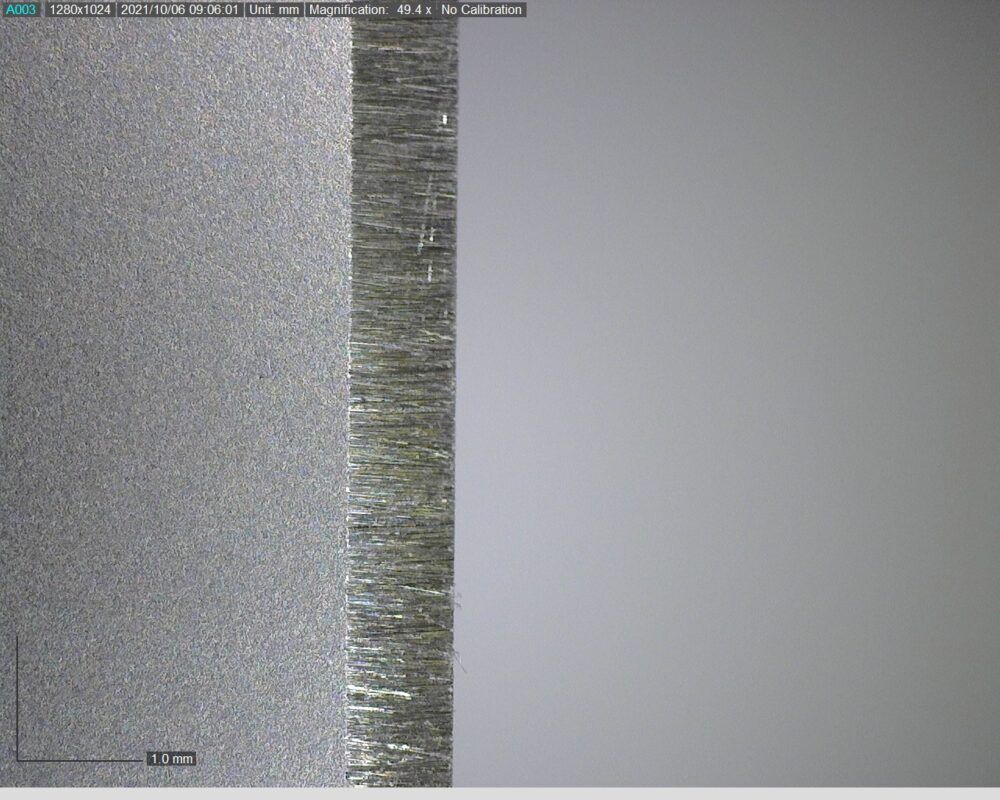

Before delving into the sharpening process, let's examine the factory edge on each Kershaw Leek. The edge appears uniform, and upon close inspection, small burrs are still discernible. It's worth noting that, under magnification, a small burr often remains after sharpening, particularly if not using a strop. This residual burr typically diminishes quickly after light use.

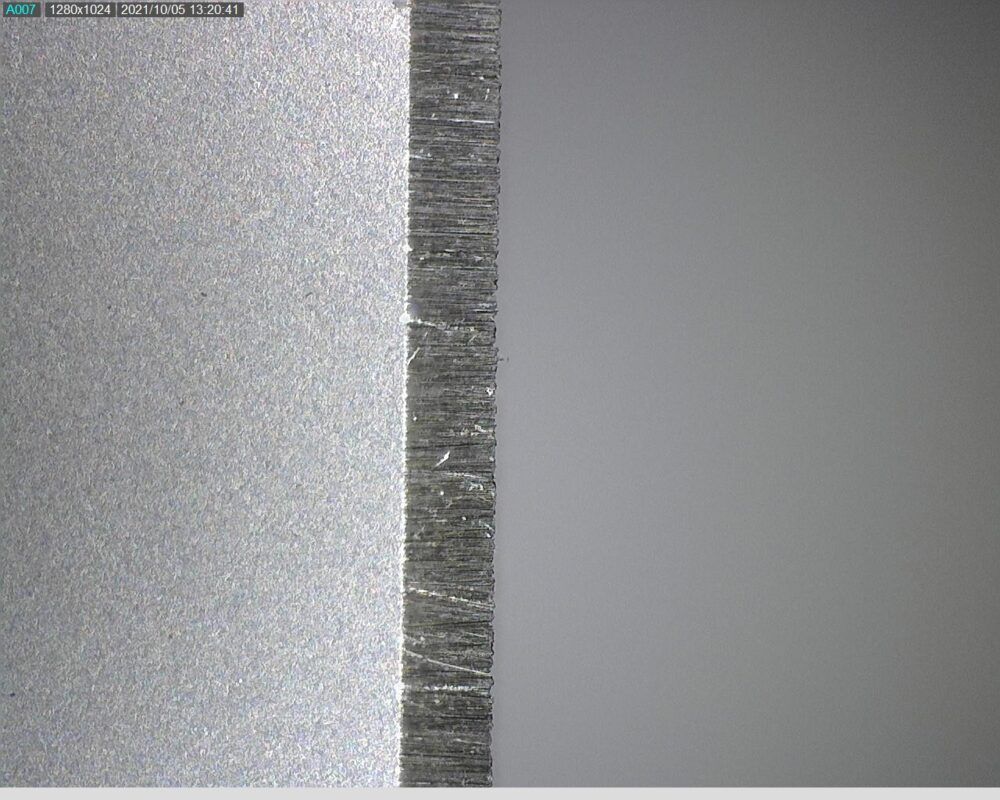

Now, let's focus on the knife sharpened with the Original Precision Adjust.

320

As you can see there is some deep striations and a rough overall finish but consistent reveal along the bevel. The burr is easily identifiable on the back side of the blade – you can see the image on the left shows a much smoother blade edge than the image on the right.

600

Using 600-grit we see some of the deep striations from the 320 stone were not totally removed. If more time was spent sharpening at this stage it would have likely removed those striations but as stated before we tried to be consistent with time spent at each stage. Overall, this already looks as good, or better than the factory edge except for the large burr still visible on the back of the blade (again, the image on the right)

Ceramic

When sharpening a knife with a ceramic stone expect consistent and beautiful results at least to the naked eye. Under magnification, however, you can see that the ceramic smooths out high spots but does not polish the deep cuts left by previous diamond abrasives. You can see a small wavy burr left over in these images, but this edge is sharp!

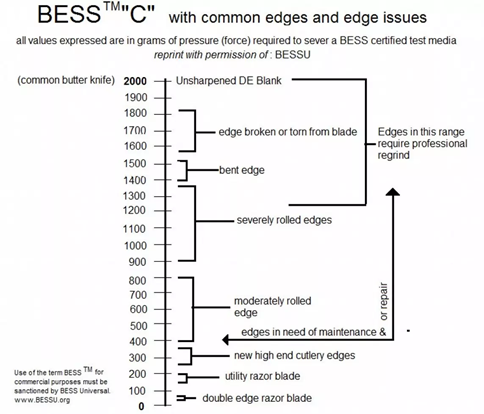

When tested this knife produces a BESS Tester score of 207 – This is almost as sharp as a utility razor blade.

Now for Kershaw Leek No. 2 which was sharpened with every grit from the Precision Adjust Elite.

220

The 220-grit produced a rougher edge than the 320, as would be expected. The amount of time spent to achieve a burr with the 220-grit was significantly less and we probably did not need to spend as much time on this step but again we tried to be consistent in time spent on each stage and it may have resulted in some deeper pitting than necessary.

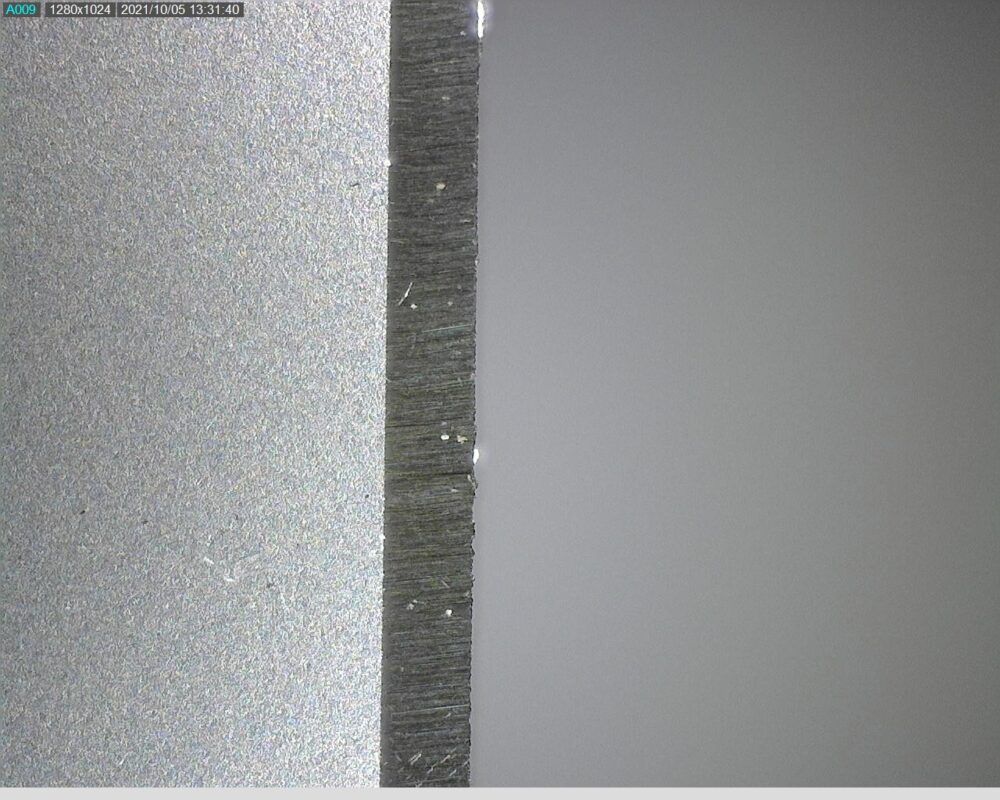

320

The 320-grit does a great job removing the scratch pattern or striations from 220 stone. The edge is a bit jagged but that is to be expected at this stage and that difference becomes less significant as we progress through the finer grits.

400

In our testing we found 400 was a critical step between 320 and 600 for removing many of the scratches from 320 that the 600 had a hard time removing. There are a few deep marks but overall greater consistency.

600

The 600-grit diamond produces a consistent and well-refined edge. Like what we saw from the factory. There are almost no deep scratch marks left over from the previous grits which is what makes the edge look so consistent.

800

The edge created with 800-grit results in a uniform satin finish. Not totally refined but very workable. The burr is much smaller, barely noticeable. With any use the burr here would fall off and you would be left with a sharp and slightly toothy edge. In our personal use we have sharpened to 800-grit then quickly stropped on leather for a razor sharp and toothy result.

Ceramic

Once again, the lustrous finish imparted by the ceramic becomes evident on the edge—particularly more pronounced after the additional progression with higher grit. To an observer without magnification, this appears as almost a mirror finish, and it was somewhat unexpected to discover numerous striations remaining when scrutinized closely. Regarding the burr, its presence is virtually eliminated. We suggest the possibility of a lingering burr only because the subsequent steps with the leather reveal a clearer picture and a more distinct edge.

Leather

The significant observation with leather is its complete removal of the burr—examining both sides indicates a clean and sharp appearance. Testing this on the BESS tester should confirm the effectiveness of the leather in achieving a polished edge.

BESS Tester score: 109

Key takeaway: Irrespective of the system chosen, a remarkably sharp knife is guaranteed. The undeniable fact is that employing more grits in the sharpening process leads to a heightened level of precision, resulting in an even sharper outcome.

The Elite System prioritizes not just achieving sharper knives, but also empowering users to craft the precise edge they desire. It allows you to decide the starting point for sharpening, determine the extent to which you want to refine the edge, and offers flexibility for touch-ups using leather or light repairs with fine diamonds.